non-standard boots

These are based on standard boots/patterns, but we will have made some small modifications to help with a customers more specialist intended use or a specific fitting problem e.g. non-standard width or change of last.

Non-standard boots (or modified standard boots) usually require a customer to visit the factory for assessment and discussion before we go ahead.

Special terms & conditions apply and customer must confirm agreement before going ahead.

Time to make non-standard boots is usually 8-14 weeks.

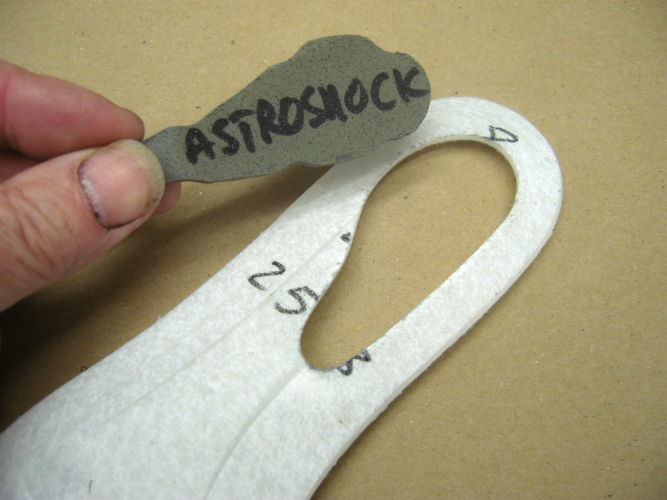

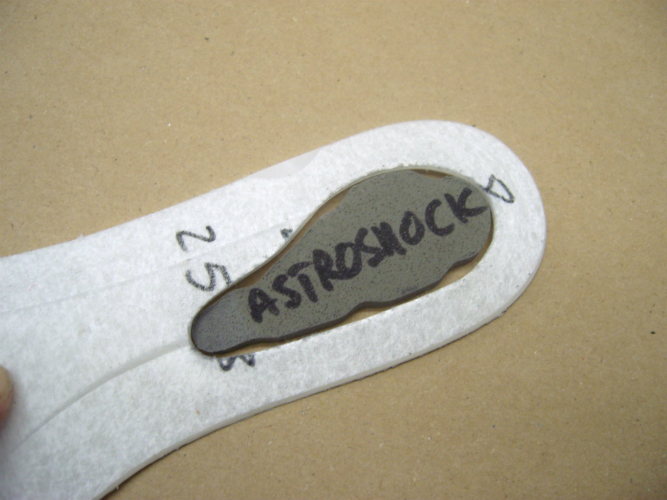

Below is just one example of a modification, the midsole fitted into a standard boot is modified in order to help a customer who had slight problems with soreness/discomfort under the heel.

CUT OUT TO ACCOMMODATE A SHOCK ABSORBING PAD

MIDSOLE & HEEL CUSHION FITTING

The most common requests are:

1. Upper materials and cushioning modifications

2. Sole and sole midlayer modification

3. Change of lasts, sizes, widths different to the standard boots.

to view terms & conditions for non-standard boots click here

SVARTZ FOOTBED UPGRADE OPTION

The retailer may offer Svartz Option Footbeds to support the foot better and improve the fitting of the boot. CLICK HERE for more information on the Svartz Footbed Option